Understanding the Fundamentals of Gas Masks

A gas mask, also known as a respirator, is a vital piece of personal protective equipment (PPE) designed to safeguard the wearer from airborne contaminants. These contaminants can range from harmful gases and vapors to particulate matter like dust and smoke. In essence, a gas mask acts as a barrier, filtering or supplying clean air to the user, allowing them to breathe safely in hazardous environments.

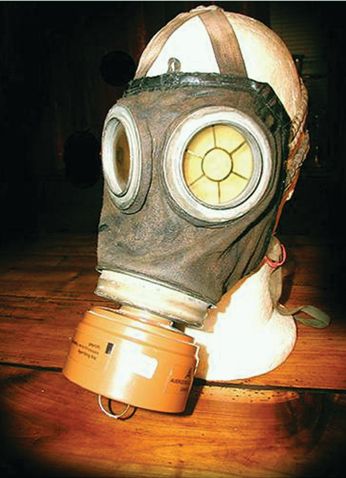

The core function of a gas mask revolves around two critical components: the facepiece and the filtration system. The facepiece creates an airtight seal around the face, preventing contaminated air from entering. The filtration system, which can include cartridges, canisters, or powered air-purifying respirators (PAPRs), removes or neutralizes harmful substances before the air is inhaled.

A Historical Journey Through Gas Mask Evolution

The history of the gas mask is deeply intertwined with the development of chemical warfare. During World War I, the widespread use of chlorine and other poisonous gases led to the rapid development of effective respiratory protection. Early gas masks consisted of simple cloth pads soaked in chemicals, but these quickly evolved into more sophisticated designs with integrated filters.

Throughout the 20th century, advancements in materials and filtration technology led to significant improvements in gas mask design. The development of activated carbon filters, for example, revolutionized the ability to remove a wide range of chemical vapors. Today, gas masks are used in various industries, from firefighting and industrial settings to military and civilian applications.

Types of Gas Masks and Their Applications

There are several types of gas masks, each designed for specific purposes and environments.

-

Air-Purifying Respirators (APRs): These masks use filters or cartridges to remove contaminants from the air. They are suitable for environments where the oxygen level is sufficient and the contaminants are known.

-

Supplied-Air Respirators (SARs): These masks provide clean air from an external source, such as a compressed air cylinder or an air compressor. They are used in environments with oxygen deficiency or high concentrations of contaminants.

-

Self-Contained Breathing Apparatus (SCBAs): These masks provide a self-contained supply of breathable air, allowing the wearer to operate independently in hazardous environments. They are commonly used by firefighters and emergency responders.

-

Full-Face Respirators: These masks provide comprehensive protection for the face, including the eyes, nose, and mouth. They are used in environments with multiple hazards, such as chemical splashes and airborne contaminants.

The selection of the appropriate gas mask depends on the specific hazards present, the level of protection required, and the duration of exposure.

The Science Behind Gas Mask Filtration

The filtration system of a gas mask is crucial to its effectiveness. It typically consists of multiple layers of materials designed to remove different types of contaminants.

Activated carbon is a common filtration material that uses adsorption to remove chemical vapors and gases. It has a large surface area, allowing it to trap and hold a wide range of substances. HEPA filters (High-Efficiency Particulate Air) are used to remove particulate matter, such as dust, smoke, and biological aerosols. They are designed to capture at least 99.97% of particles 0.3 microns in diameter.

In some cases, chemical filters are used to neutralize specific contaminants through chemical reactions. These filters are designed to target specific hazards, such as acid gases or ammonia.

Modern Applications and Future Innovations

Today, gas masks play a crucial role in various industries and applications. They are used in industrial settings to protect workers from chemical exposures, in firefighting to provide respiratory protection in smoke-filled environments, and in military and law enforcement to safeguard against chemical and biological threats.

Ongoing research and development are focused on improving the performance, comfort, and usability of gas masks. Innovations such as advanced filtration materials, lightweight designs, and integrated communication systems are enhancing the effectiveness and versatility of these vital protective devices.

As the world continues to face new and evolving threats, the role of gas masks in ensuring personal safety and protection will remain paramount.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.